Understanding the mechanism and impact of column compartment thermostatting and mobile phase preheating on chromatographic separations is important in liquid chromatography. This application note demonstrates the effect of differences in column compartment design on resolution and selectivity of a critical pair of temperature sensitive compounds across various LC instrument vendors. General consideration of column compartment thermostatting design and mobile phase preheating during method development and method transfer is also provided.

Separation temperature plays an important role in high performance liquid chromatography (HPLC) since it can influence retention time, selectivity, and peak shape. While temperature is one of the key factors to control during development and transfer of LC methods, the understanding of column thermostatting and mobile phase preheating and their impact on chromatography are often incomplete.

In today’s analytical instrument market, most LC systems include either a dedicated column compartment or options of various types of column compartments. In general, there are two common types of column compartments, block heater and circulation air types.1,2 The different thermostatting mechanisms can result in differences in heat transfer efficiency, temperature equilibrium, and the creation of a temperature gradient in the column. For adequate mobile phase preheating, most LC vendors provide preheaters that will heat the mobile phase to the set method temperature prior to solvent introduction into the column. Mobile phase pre-heating can be passive or active. Passive preheaters are capillaries of a specified length that are in direct solid contact to a temperature-controlled surface in the column compartment. Active preheaters employ an internal heating element to actively control the eluent temperature. All these variables can impact the transferability of temperature sensitive separations.

To illustrate this, we conducted a temperature sensitive separation on the ACQUITY Arc System configured with the ACQUITY Column Manager (CMA), a new extension of column compartments to ACQUITY Arc and ACQUITY Arc Bio family.3 The same experiments were also carried out on LC systems from various vendors with different column thermostatting and preheater designs. While many instrument parameters can have impact on LC separations, this application note will focus on the impact of column compartment characteristics and mobile phase preheating.

Waters Analgesic Mix Standard (p/n 186006350) was prepared in 90% water/10% acetonitrile at a concentration 50 µg/mL.

|

LC Conditions |

|

|---|---|

|

LC system: |

ACQUITY Arc with CMA |

|

Column temp.: |

35 °C, 40 °C, 45 °C, 50 °C, 55 °C, 60 °C |

|

Equilibrium time at each temp.: |

30 min |

|

Active preheater: |

with preheating – preheater enabled without preheating – preheater disabled |

|

Detection: |

2998 Photodiode Array (PDA) Detector |

|

Wavelength: |

245 nm |

|

Column: |

XBridge BEH C18 Column, 130 Å, 3.5 µm, 4.6 mm x 150 mm (p/n 186003034) |

|

Injection volume: |

5 µL |

|

Flow rate: |

1 mL/min |

|

Mobile phase A: |

Water/0.1% formic acid |

|

Mobile phase B: |

Acetonitrile/0.1% formic acid |

|

Gradient: |

15 to 30% B/7 min |

|

Chromatography software: |

Empower FR3 |

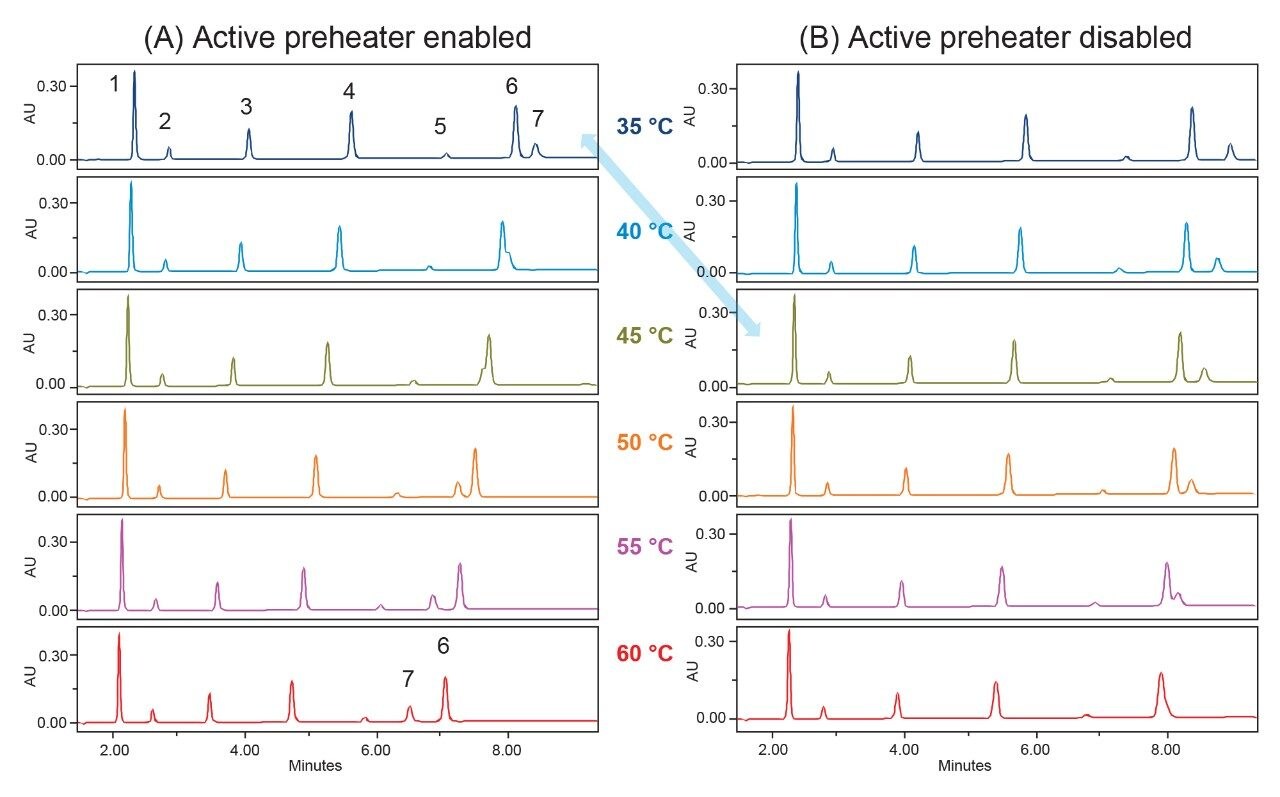

As previously studied, separation of an analgesics mix is temperature sensitive.4 Figure 1 compares the analgesics mix separation at set column compartment temperatures with the active preheater enabled or disabled on ACQUITY Arc System configured with CMA. In the sample mix, component 6 (phenactein), and 7 (salicylic acid) are a critical pair with resolution and selectivity being strongly impacted by temperature. This pair was used as a probe to study the impact of column compartment thermostatting and preheating on LC separations.

As shown in Figure 1, a dramatic difference in selectivity and resolution of the critical pair was observed with and without preheating of the mobile phase (column compartment was set to the temperature shown in Figure 1). The general trend is that the separation profile at a higher temperature without preheating (see Figure 1B at 45 °C) was similar to the separation profile at a lower temperature with preheating (see Figure 1A at 35 °C). Without preheating, the mobile phase entering the column has not fully equilibrated with the set temperature of the column oven, therefore the separation is carried out at a lower temperature than the set temperature of the column compartment. Even though all of analgesics mix peaks shift to shorter retention times with increasing temperature, the degree of the retention time shift with preheating was greater than the retention time shift without preheating.

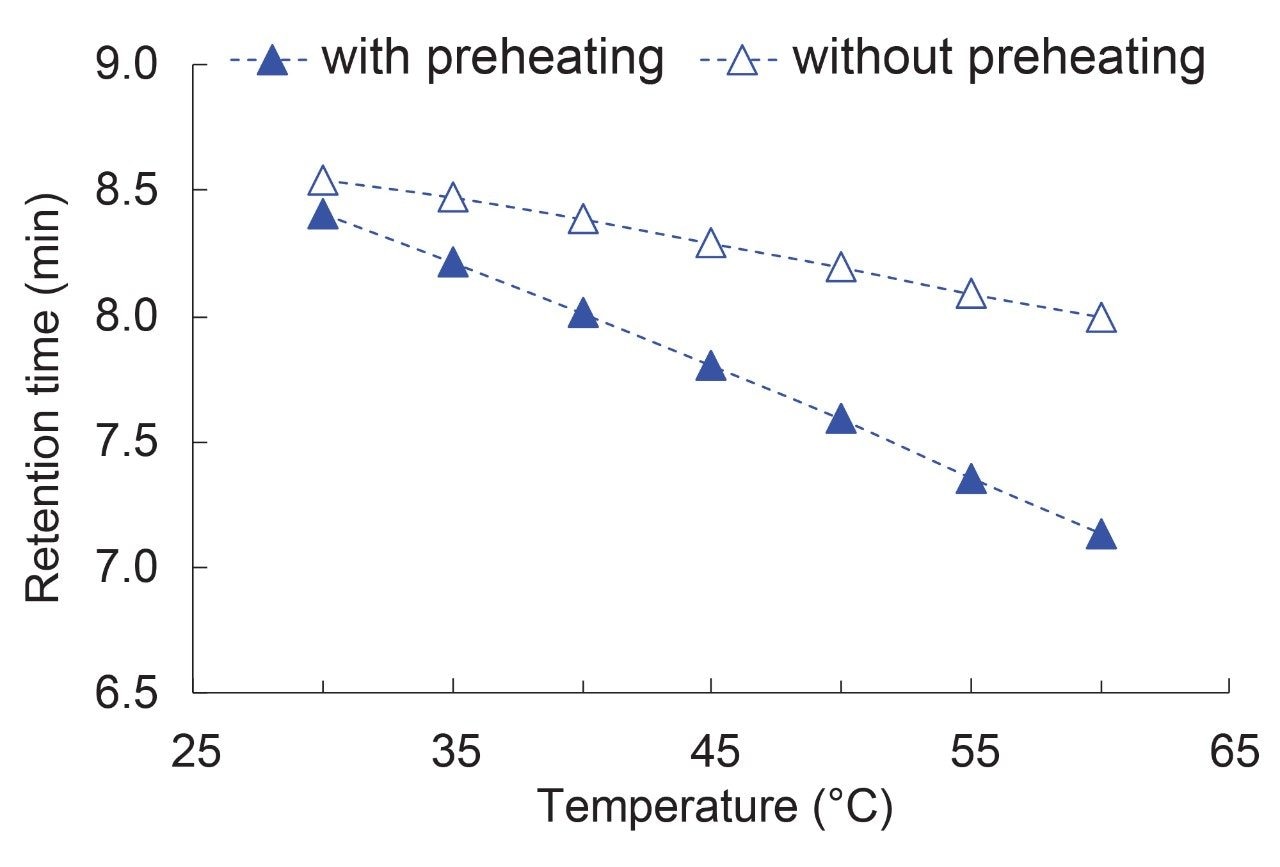

Figure 2 shows the retention time of peak 6 changing with temperature with the active preheater enabled (with preheating) and with active preheater disabled (without preheating). With the preheater enabled, the slope of retention time with temperature is greater than the slope without preheating. This indicates that the mobile phase in the analytical column aligned with the set temperature more rapidly with preheating than without preheating. With the preheater disabled, there might be a mismatch of the temperature of the column wall and mobile phase flow within the column, creating a temperature gradient across the column.

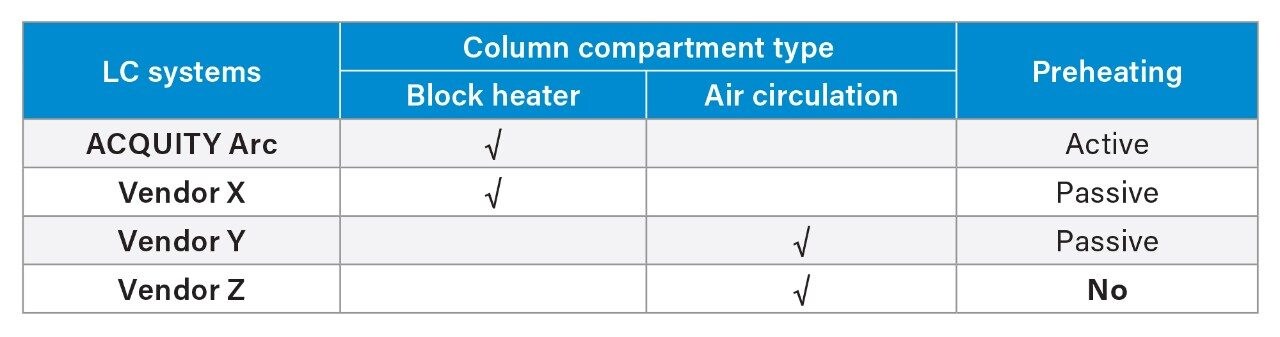

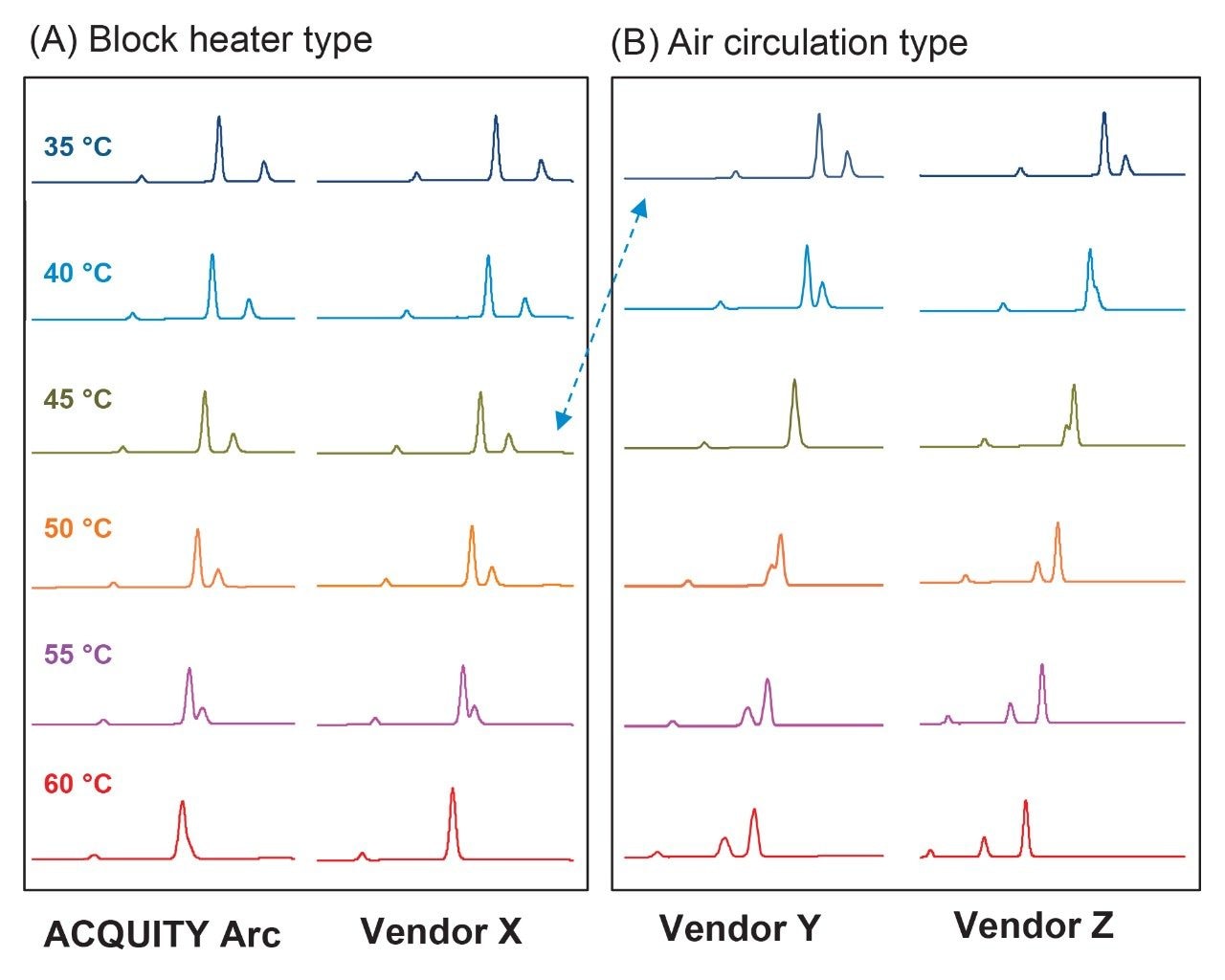

In addition to solvent preheating, column thermostatting design can impact the separation as well. Four UHPLC systems with different types of column compartment thermostatting mechanisms were selected for the study (Table 1). Among them, the ACQUITY Arc System (with active preheater) and vendor X (with passive preheater) are block heater type. Vendor Y (with passive preheater) and vendor Z (with no preheater) are air circulation type. In general, the block heater type provides efficient real-time column wall heating since the column directly contacts the heat source. Air circulation type is based on air bath concept. Compared to metal, air is a poor heat conductor, hence an air bath is less effective at controlling the column temperature in real-time. However, the effectiveness of column heating can be enforced by circulating the air in the air circulation type column compartment.2

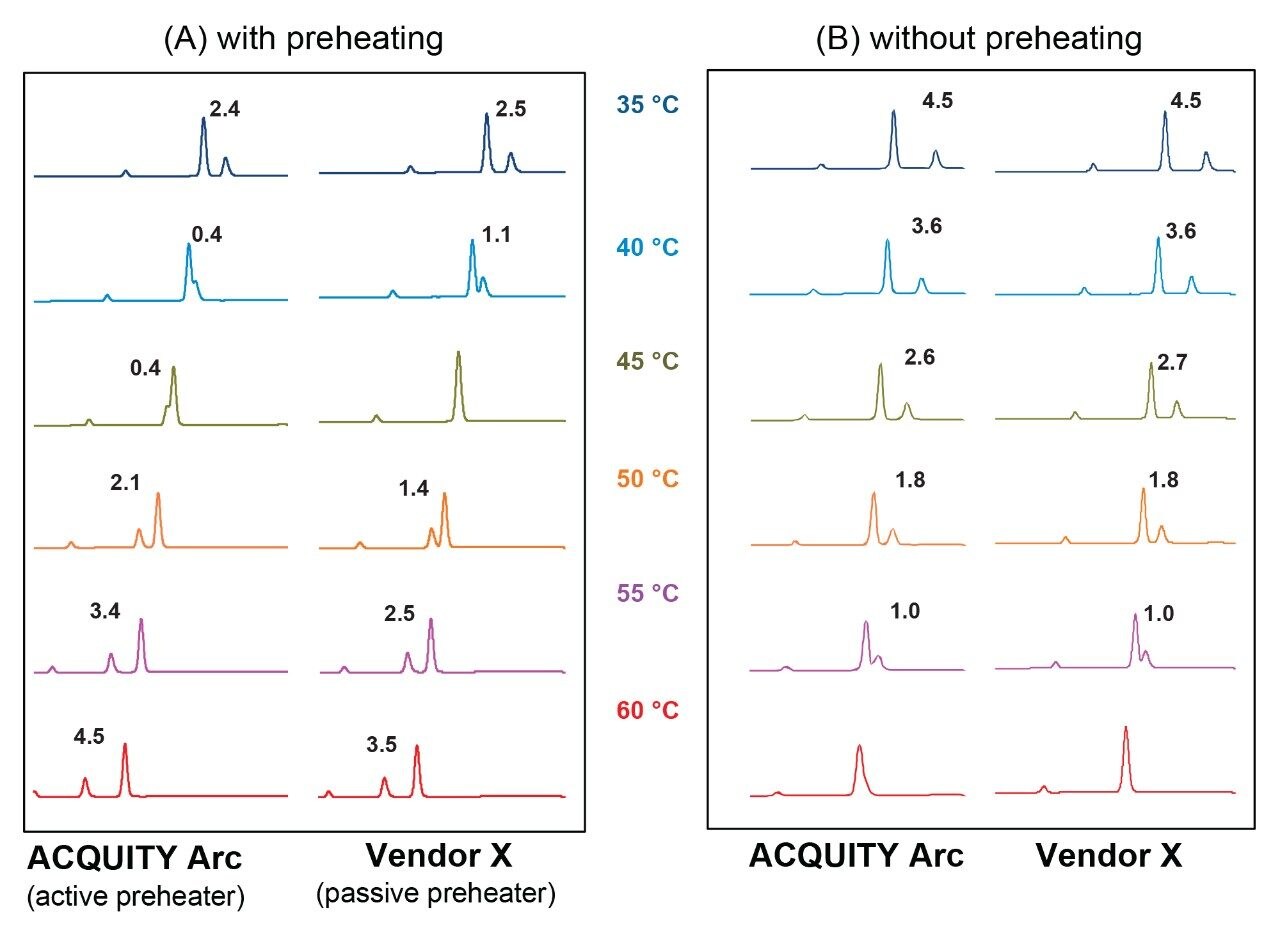

For the ACQUITY Arc System and vendor X, which both have similar U-shape design block heaters, similar selectivity, and resolution of the critical pair was obtained with preheating (Figure 3A) and without preheating (Figure 3B) respectively. The preheater types (active vs. passive) do not have significant impact on the separation profile of the critical pair.

On the other hand, without preheating mobile phase, the selectivity and resolution of the critical pair on the block heater type (Figure 4A, ACQUITY Arc and vendor X) is significantly different from those on air circulation type (Figure 4B, vendor Y and vendor Z). On block heater type, the separation profile of the critical pair at higher temperature (see Figure 4A, 45 °C) is similar to the separation at lower temperature on air circulation type (see Figure 4B, 35 °C).

However, when preheating the mobile phase, the separation profile of the critical pair behaved similarly on block heater type (ACQUITY Arc System) and air circulation type (vendor Y)(Figure 5). This observation indicates that the difference on the temperature equilibrium within the column due to different thermostatting designs can be minimized by preheating the mobile phase.

In this application note, we carried a temperature sensitive separation study on ACQUITY Arc System configured with CMA and LC systems with different thermostatting designs from various vendors. The study demonstrated that the column compartment characteristics, including thermostatting type and mobile phase preheating, greatly impact temperature sensitive separations. Some general considerations when developing and/or transferring methods among different LC systems are:

720007137, February 2021