Fast Discrimination of Industrial Polyamide Gears with Varying Regrind Material Content Using Advanced Polymer Chromatography for SEC/GPC

Abstract

This application note demonstrates the advantages of using the Waters ACQUITY Advanced Polymer Chromatography (APC)™ System for size exclusion chromatography (SEC)/gel permeation chromatography (GPC) analysis of polyamide blended with various percentages of regrind material with hexafluoro isopropanol (HFIP) as the solvent.

Benefits

- A 15-minute per sample analysis time compared to traditional GPC of 45-minute run time

- Polyamide GPC analysis option that uses less solvent and creates less hazardous waste

- APC Isocratic Solvent Manager (ISM) system with demonstrated performance for the analysis of polymeric samples using a variety of solvents including HFIP

Introduction

GPC is an analytical technique used to characterize polymers that use the addition of recycled (regrind) material. The recycled polymers being used as a raw material are only acceptable when performing like the original non-recycled polymers. Therefore, polymer properties such as molar mass distributions, molar mass averages, and polydispersity must be sustained for the final product properties to be preserved. This is important as reprocessing of the polymer could potentially cause chain-length degradation and have properties different from the original starting material.

Due to the chemical resistance of polyamides, such as nylon 6,6, dissolving the polymer in an organic solvent for analysis using GPC is challenging.1 Industrial manufacturers use high temperature (HT) GPC (>100 °C) to determine the molecular weight distribution of these nylon polymers, and the analysis often uses ortho dichlorobenzene (ODCB), trichlorobenzene (TCB), m-cresol or N-methyl pyrrolidone (NMP) as the mobile phase with traditional styrene divinylbenzene (SDVB) GPC columns. However, this technique consumes large amounts of solvent which creates large hazardous waste costs, and a lengthy 45-minute analysis time.2-4

In this study, an alternative approach to HT-GPC analysis for polyamides (such as nylon 6,6) is employed with HFIP mobile phase and an APC system.

Experimental

In this APC analysis, an HFIP mobile phase with salt additive was used to run a size-based separation of various polyamides (Table 1). Polyamide gear samples containing virgin and varying percentages of regrind material were obtained from Thyssenkrupp Presta AG, Liechtenstein. The samples were dissolved in HFIP at 1 mg/mL overnight in scintillation vials and transferred to instrument vials.

LC Experimental Conditions

|

System: |

APC™ with ISM |

|

Pump: |

Isocratic |

|

Mobile phase: |

Hexafluoro-2-propanol w/0.1 % sodium Trifluoroacetate (NaTFA) |

|

Wash/purge: |

Hexafluoro-2-propanol |

|

Seal wash: |

80/20 Water/Isopropanol |

|

Seal wash rate: |

2 min. intervals |

|

Flow rate: |

0.45 mL/min. |

|

Run time: |

15 min. |

|

Sample temperature: |

20 °C |

|

Syringe draw rate: |

Automatic |

|

Sample conc: |

1 mg/mL |

|

Injection volume: |

20 µL |

|

Column temperature: |

50 °C |

|

Column set: |

ACQUITY APC XT™: 450 Å (2.5 µm, 4.6 x 75 mm), p/n 186007253 125 Å (2.5 µm, 4.6 x 75 mm), p/n 186006998 45 Å (1.7 µm, 4.6 x 75 mm), p/n 186006993 |

|

Detector: |

RI (50 °C) |

Data Management

Instrument control as well as data acquisition, processing, and reporting were done by Empower™ 3 Chromatography Data System.

Results and Discussion

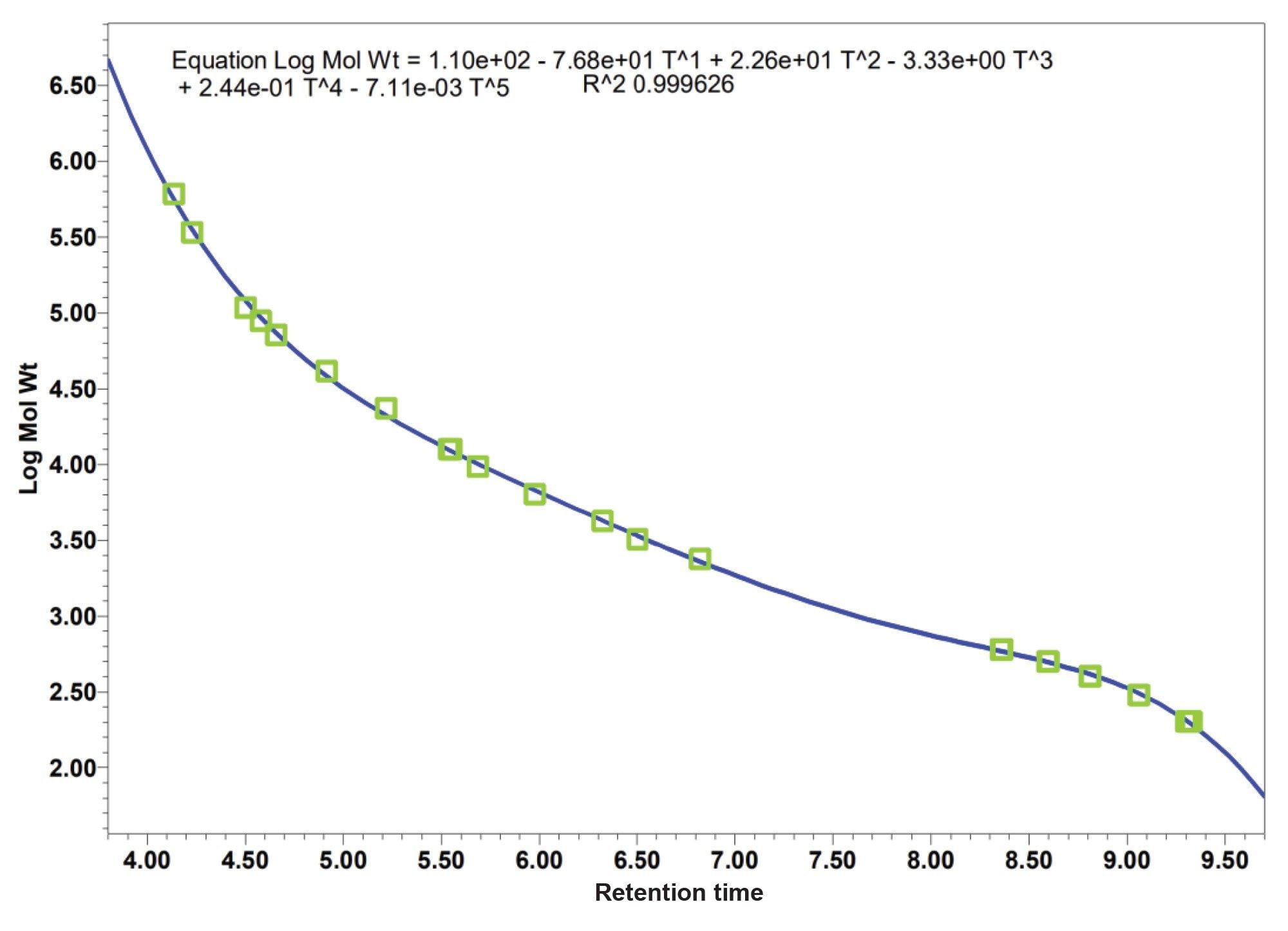

The polymethyl methacrylate (PMMA) calibration standards were first analyzed to establish a relative calibration curve prior to the analysis of gear samples (Figure 1).7 The highest molecular weight points were on a bend in the calibration curve, and this is due to the lower resolution of a shorter separation path and shorter column, yet this does not affect the quality of the unknown polyamide sample analysis due to their eluting in the linear range of the curve. A 5th order curve was used to obtain an excellent R2 value of 0.9996 (Figure 1).

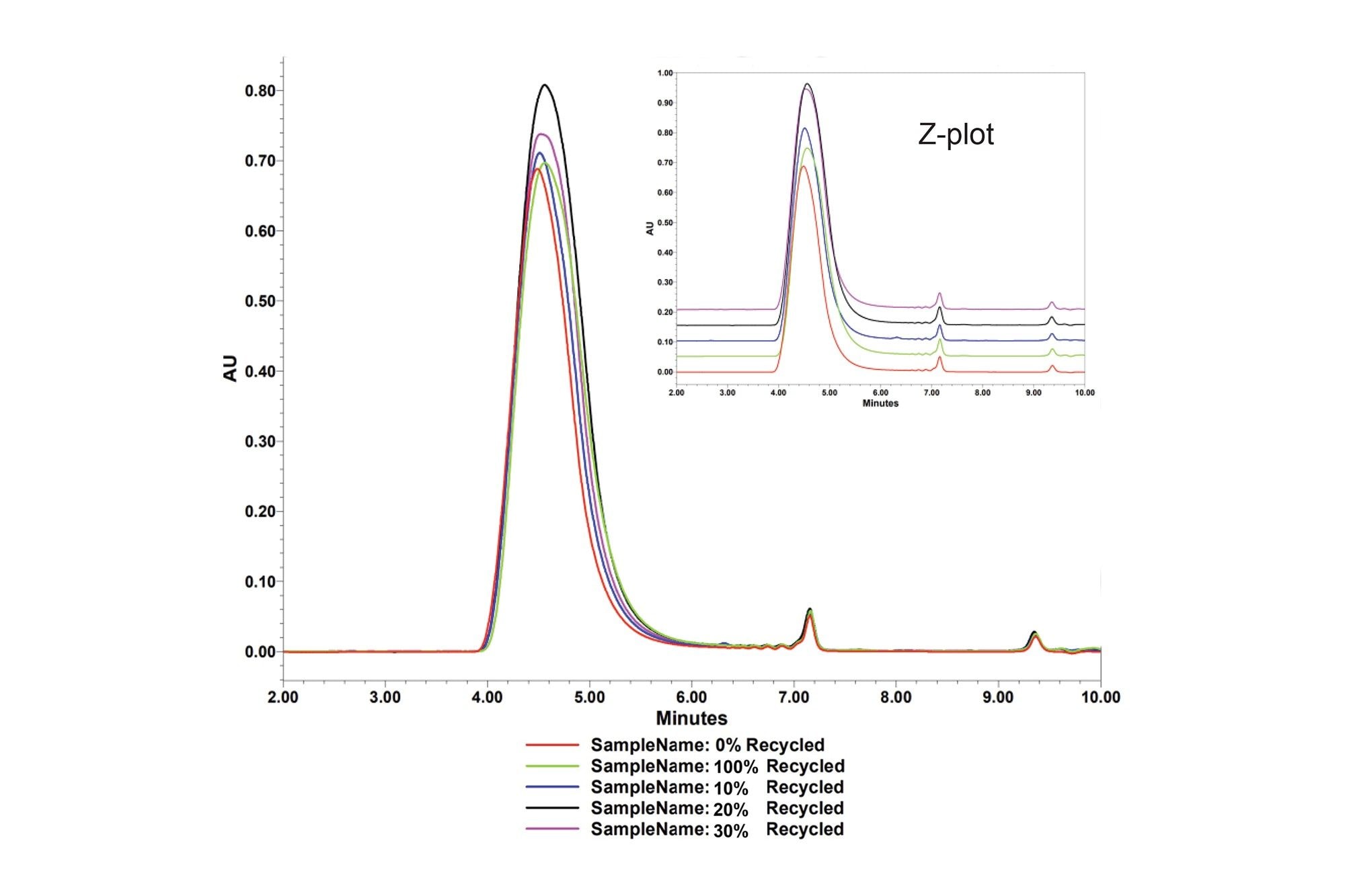

The unknown polyamide gear samples were integrated and calculated using the relative calibration PMMA standard curve and overlayed to display the differences in peak shape and height (Figure 2). The samples were prepared and injected identically. Therefore, peak differences are based on the recycled material added to the ratio. As more recycled (regrind) material is added, the peaks have a higher retention time and slightly lower and broader shape. This change in shape change indicates a lower molecular weight and a broader molecular weight distribution. Changes in polymer molecular weight and distribution can be indicative of a lower heat and impact resistance, which is often confirmed through thermal analysis using a differential scanning calorimeter (DSC).8

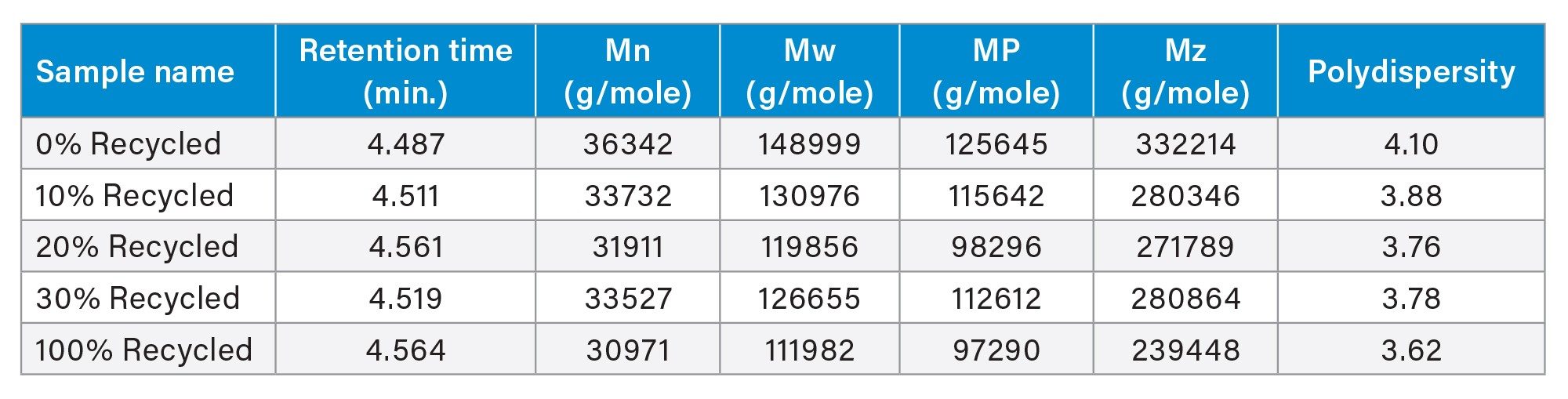

Although the overlay of peaks does not appear to have large differences in peak shape, the calculated molecular weight is a 24% difference between the zero percent and the 100 percent peaks. The gear containing zero percent recycled nylon has a peak maximum (MP) molecular weight of 127 k Dalton (Da) compared to the 97 k Da gear with 100 percent recycled polymer. The difference in the peak values is also seen in the weight average (Mw), number average (Mn), z-average, and polydispersity index (PDI) in table 4. Each change in these various values can affect the properties of the polymer strength, melt flow, and flexibility.

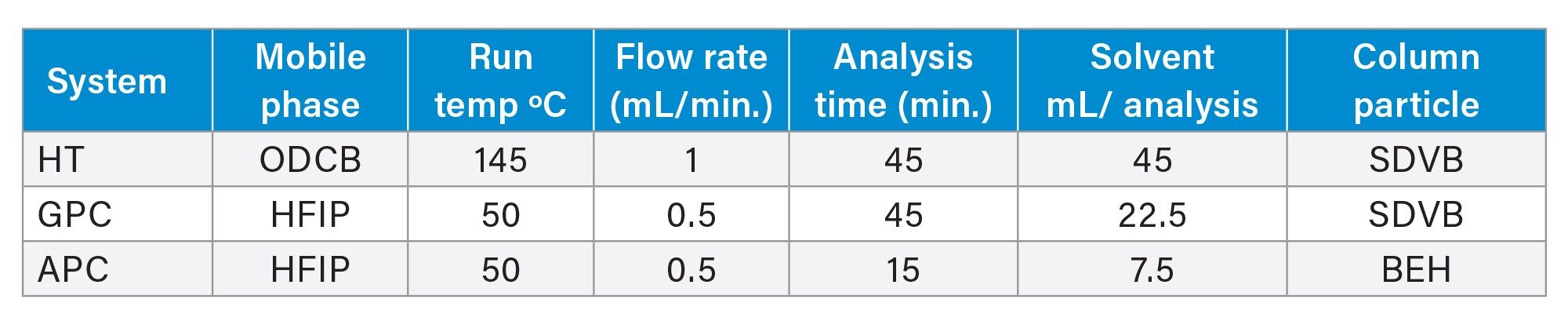

The APC system, with an ACQUITY APC XT™ Column bank operated at high pressures, enables the HFIP size separation of polyamides in 15-minutes as compared to the HT and HPLC systems. In addition to high pressure capability, the APC XT Columns are resistant to solvent swelling. The advantages of using the APC option over a HT GPC is a three-fold time savings and six times less solvent consumption. Less solvent consumption equals less hazardous waste which contributes to an improvement in sustainability (Table 3).9

Conclusion

The results from the experiments described demonstrate that the APC has the capability to differentiate polyamide gear samples containing varying percentages of regrind material (considered here as recycled) dissolved in HFIP with a calibration curve having and R2 value of 0.9996.

This analytical method delivers the results three times faster than traditional GPC with a 15-minute analysis per injection. The shorter run time uses less than 7 mL of HFIP solvent per injection, as compared to traditional GPC using greater than 22 mL per injection.

The analytical approach described has the potential to increase laboratories sample throughput offering a more sustainable, cost-effective separation option and a viable alternative to high temperature GPC.

References

- Palmer, Robert J. (2001). "Polyamides, Plastics". Polyamides, Plastics. Encyclopedia of Polymer Science and Technology (4th ed.). John Wiley & Sons, Inc. doi:10.1002/0471440264.pst251.

- Beginners Guide to Size Exclusion Chromatography.

- Wudy, Katrin & Drummer, Dietmar. (2018). Aging effects of Polyamide 12 in Selective Laser Sintering: Molecular Weight Distribution and Thermal Properties. Additive Manufacturing. 25. 10.1016/j.addma.2018.11.007.

- Chen, An-Liu & Wei, Kuan-liang & Jeng, Ru-Jong & Lin, Jiang-Jen & Dai, Shenghong. (2010). Well-Defined Polyamide Synthesis from Diisocyanates and Diacids Involving Hindered Carbodiimide Intermediates. Macromolecules. 44. 10.1021/ma1022378.

- APC System Chemical Compatibility Guide.

- Christian Wold, Elena Uliyanchenko (LCGC Europe), Ultra-High Size-Exclusion Separations of Engineering Plastics: Challenges and Opportunities, https://www.waters.com/webassets/cms/library/docs/lcgc_uliyanchenko_engineering_plastics_with_uhpsec.pdf.

- Don Trinite, Waters Corp., 1360 N. Wood Dale Rd., Suite C, Wood Dale IL 60191.

- Browne J., Thermal Analysis of Polyamide 66 Gears with Added Recycle, New Castle, DE, January 2023, https://www.tainstruments.com/thermal-analysis-of-polyamide-66-gears-with-added-recycle/.

- Richard Mendelsohn, Jennifer Gough, Fast, High-Resolution Analysis of Polydimethylsiloxanes in Toluene With Advanced Polymer Chromatography Coupled to Refractive Index Detection. Waters Application Note. 2022. 720007658.

720007824, December 2022